Mining Telephone

This article considers how VoIP Mining Telephone / Mine Phone Systems can be used to improve mining production and safety whilst reducing costs. It will also look at critical issues to consider when installing an effective underground mining communications system.

A challenge for the Mining industry

Mining operators are faced with three key objectives: 1. Increase production output from the mine, 2. Reduce operational costs, and 3. Improve safety.

In order to increase production, a mine site owner has to focus his/her attention on speeding up the drilling/ boring, whilst removing bottle-necks when it comes to delivering the metals quicker to the surface. A mine site owner is also tasked with reducing operational costs associated with the mine operation. This can be achieved in numerous ways, such as installing automated systems or evaluating other ways of saving money on fixed outgoings such as maintenance bills. Finally, a mine site owner need to be focused on safety at all times, minimising the risk for injuries and fatalities

Safety has long been a controversial issue in the mining business. While mining today is substantially safer than it was in the previous decades, mining accidents are still relatively frequent and are often very high profile, such as the Quecreek Mine Rescue saving 9 trapped Pennsylvania (USA) coal miners in 2002 or the Copiapó Chile mining accident in 2010 when 33 miners became trapped underneath the surface..

The constant threat of technology failure and mining accidents remains a significant concern for many miners throughout the world, including Indonesia, South Africa, Chile, Brazil, Peru, Russia, China, Mongolia, USA, Canada and Australia.

Accidents can easily happen in sub-surface mines, both in terms of failures in construction as well as un-intended exposure to harmful gases, oxygen starvation, heat and dust. An example of a challenging environment, is the TauTona mine in South Africa, which began operation in 1962. By 2008, the mine reached some 3.9 km underground, making it the deepest mine in the world, employing some 5,600 miners. Air conditioning equipment is used to reduce the heat from 55 centigrades down to a bit more bearable 28 centigrades, but even so, the mine remains an extremely dangerous place to work and an average of five miners die in accidents each year. In the 2008 financial year, four employees were killed at the TauTona mine.

The Answer

The success of any mining operation depends on effective two-way communications. From maximising production and preventing disruptions to ensuring life safety of mining workers, an effective communications tool is one of the most important installations in a subsurface mine.

VoIP mining telephones are essential in order to prevent damage, reduce down-time and to increase production. An IP-based mining telephone / mine phone system is also important for mine site rescue efforts, to deal with injuries, fatalities and entrapment situations. A VoIP telephone installation can also help reduce cost, by virtue of converging voice & data networks and by eliminating large telecom bills.

Norphonic has a history of delivering Heavy Duty VoIP telephones into some of the world’s most challenging areas, ensuring essential voice communications when it is most needed. In the remaining part this article we shall look at some of the issues that needs to be addressed when selecting an effective telephone solution in your underground mining application.

A Typical Underground Mining Communications System

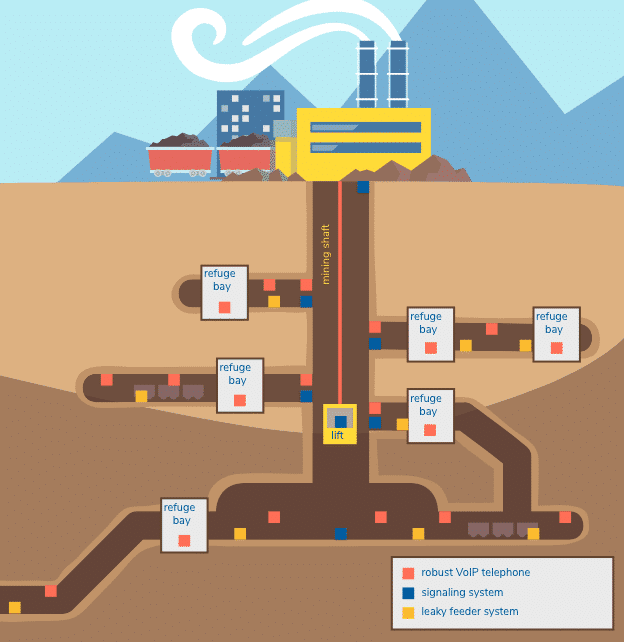

The below figure shows a typical Heavy Duty VoIP Telephone installation within a sub-surface mining environment. Telephones can either be connected in a circle formation to provide a redundant network or in a line to connect directly to a PBX. The distance between telephones can differ greatly in various environments, but it is usually recommended that organisations do not extend beyond 150 meters between telephones for safety reasons.

The schematic shows a mine shaft going down into the underground mine. Such mining shafts can sometimes be 12 stories deep and reach 3-4 kilometers below the surface. There are usually many horisontal “arms” shooting off the main mining shaft. These horisontal tunnels can be many kilometers long.

Mining Telephone, Mine PhoneIn the above schematic there are 3 underground communication systems installed: a robust VoIP telephone system; a signaling system; and a leaky feeder system. There are a number of reasons why a mining company may need several communications solutions installed. First, local governments often legally require mining companies to have at least two different communication systems in case of a critical system failure. Secondly, there are practical / operational reasons why a company may opt to have more than one communication system installed.

In the example schematic drawing above, Robust VoIP Telephones (marked in RED) are installed at regular intervals on the fiber optic network running along the mining tunnels. This allows miners to communicate with each other or with the central control room at surface level. These VoIP telephones are also installed in the Refuge Bays (marked in YELLOW). Refuge Bays are specifically constructed underground evacuation rooms stocked with drinks, foods and medical supplies for miners in case of emergency evacuation. A signalling system is also installed close to the mining shaft (marked in BLUE), allowing miners to call for the elevators (lift) and robust VoIP telephones are installed next to the signaling system devices to allow clear communication with the elevator operator at surface. In the example, a leaky feeder communications system is also installed (marked in GREEN) which consists of a coaxial cable which emits and receives radio waves. The cable is leaky in that it has gaps or slots in its outer conductor to allow signal to leak into or out of the cable along its entire length.

Why Norphonic VoIP?

VoIP telephones (VoIP is an acronym for “Voice over Internet Protocol”) allows users to make telephone calls using their existing data networks rather than from the traditional analogue land line service. These calls can be made from one computer to another or to landlines as well. There are several important reasons why most organisations now are converting their system into a VoIP telephone system. This includes both economical and practical safety reasons:

First of all, a VoIP telephone can use the existing LAN / IP data networks to carry voice, it offers much lower installation and operating costs because they can be integrated into existing IP/LAN networks. There is also no requirement for the installer to be an electrician. A benefit with the Norphonic Mining Telephone is that it is based on open SIP standards. This means that you can use the Norphonic SIP function and transfer the calls to any IP PBX free of charge over your IP network. The phone can be powered over ethernet eliminates the need for an external power supply.

Secondly, Norphonic VoIP mining telephones have in-built software features which makes this VoIP telephone very attractive in terms of reducing cost underground mining applications. For example, all Norphonic Heavy Duty VoIP telephones comes with a self-monitoring and fault check function as standard. This is a highly useful feature, as it allows central control room staff to automatically know if the telephones are working at any given time. The control room can also get information about the telephone components, if the telephone hook is left in an on/off position etc. This is obviously an important safety feature in many underground applications as. The monitoring features provides the control room staff a better overview of the mine.

Third, with Norphonic robust VoIP mining telephones, the control room staff can use SNMP/HTTP to upload software updates from a central location, restart the telephone, or control other telephone components remotely, thereby slashing the maintenance costs usually encountered with comparable analogue systems.

Fourth – and finally – IP is the future of all industrial comms. All modern system today runs on IP technology (ventilation fans, fire detection, surveillance cameras, access control, gas detection etc) and it is only natural to use that same network for telecoms. Not to mention saved calling cost by using your existing data network for telecom purposes.

The Norphonic VoIP Mining Communications System

The Norphonic Heavy Duty VoIP Mining Telephone is a robust, weather resistant telephone built to withstand extreme temperatures, humid and dirty environments. It is perfectly suited to underground mining areas with an overall weather resistance to IP65. The unit is manufactured in a durable aluminium casing, resistant to rust, condensation and corrosion. The hook switch has no moving parts, making the telephone ideal for use in mining environments exposed to high levels of dust or grime. It comes complete with an 80 dB ringer as standard and an optional visual Flashing Light Beacon, ideal for use in noisy areas where a ring may not easily be heard.

A key feature is the Quality of Service (QoS) functionality, which enables optimal prioritizing of network traffic and impeccable transfer of voice and data. The telephone can be maintained and upgraded from a remote location; thereby slashing maintenance costs associated with conventional telephone systems. A Self-Monitoring and Fault Check function is also included, ensuring maximum up-time and further saving maintenance costs.

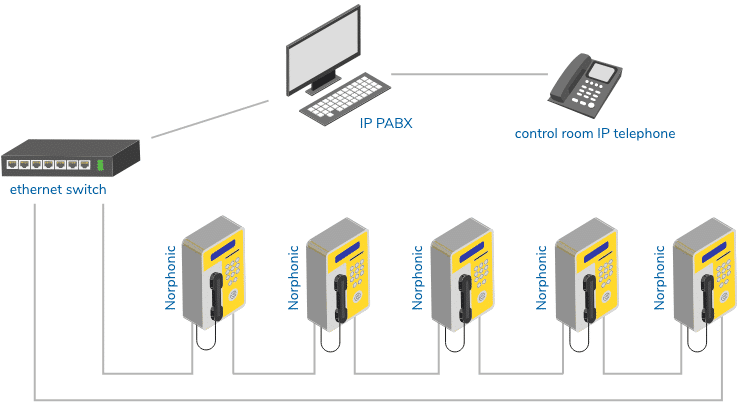

The Norphonic Heavy Duty VoIP Mining Telephone solution is typically connected to an IP based Public Branch Exchange (PBX) on an Ethernet network as shown in the example below:

Example Norphonic VoIP Mining telephone solution

Self-Monitoring and Fault Check Functions

To further reduce maintenance costs and improve overall uptime, Norphonic offers automatic health-checks and fault sensing on all VoIP mining models. This valuable feature gives the control room staff an immediate notification if there is a connectivity or function fault, thereby ensuring timely repair and maintenance of your mine site communications system. This function offers surveillance capabilities of:

- Hook sensing (i.e: hook off/on)

- Audio Self Test (microphone / headset check)

- Firmware version and firmware update status

- Telephone state monitoring

The audio self-test involves testing the function of the SIP software, audio circuits and the handset by playing and recognizing a set of DTMF tones in the handset at pre-configured time intervals. The alarms are reported over ethernet. The phone can provide Modbus UDP, Modbus TCP or SNMP traps for the self-test and on-hook / off-hook event. The advantage of using SNMP or Modbus protocols is that these are standardised tools for monitoring other network equipment, including switches, routers, PBX systems, VoIP gateways and pretty much anything you want to monitor inside your mining environment.

SCADA or Business Process Management Integration

The inclusion of Modbus TCP, UDP and SNMP open standard protocols in all Norphonic VoIP telephone models mean that it easy to integrate Norphonic mining telephones with your existing supervisory control and data acquisition (SCADA) system.

Norphonic Heavy Duty VoIP Telephones can therefore easily integrate with existing IT infrastructure such as business process management, SCADA systems or surface-based control equipment. This provides unique flexibility when integrating process-reported alarms.

Ethernet Networks are Ideal for Underground Communications

Modern and efficient mining facilities utilise improved control methods and increased mechanisation to achieve optimum productivity. Ethernet networks have a proven track record within underground areas to monitor, analyse and control both equipment and facilities, increasing both safety and production efficiency.

Fiber Optic / Ethernet networks are today used to manage, control and interconnect a wide range of technology in underground mining environments, including:Ethernet networks are today used to manage, control and interconnect a wide range of technology in underground mining environments, including:Fiber Optic / Ethernet networks are today used to manage, control and interconnect a wide range of technology in underground mining environments, including:

- VoIP Telephone systems

- Conveyor Belt, and Ventilation Control systems

- SCADA systems

- Interlocks, and Access Control systems

- Fire Detection systems

- Remote Video Monitoring systems

What to look for in a VoIP Mining Telephone?

There are many issues that needs to be addressed prior to commissioning an IP mining telephone, such as evaluating the installation environment, functionality and temperature ranges. Below are some key pointers to look at when choosing your underground communication system:

- Can the system work with your existing systems and infrastructure? The key thing to look for in this regard, is to examine if the telephone is built on Open Standard SIP technology. Norphonic Heavy Duty VoIP systems are built on Open Standard SIP technology, and tested to be compatible with all major PBX and network systems (Alcatel, Cisco, Asterisk, Broadsoft etc).

- Is the system future proof? Can the system be upgraded or changed in the future without having to change all the telephones and the entire network? All Norphonic Heavy Duty telephones can be changed with other network equipment (PBX, switches etc) without loss or differentiation to the level of service.

- Is the telephone dust and water proof? Underground mines are some of the most challenging areas in the world, exposed to extreme levels of dust and water. The highest level of dust protection is essential. The ingress IP rating to IP65 is therefore recommended in all mining applications. See definition of Ingress Protection in the below Glossary for further information

- Is the telephone condensation proof? –This can otherwise lead to severe problems in operation as water can easily form inside the unit, affecting performance.

- Does the hookswitch contain moving parts? All Norphonic Heavy Duty VoIP telephones do not contain moving parts, and can therefore operate in extreme areas where dust or exposure to grime is a challenge for traditional telephone systems.

- Can the system work in extreme temperatures? Underground mines can be notoriously hot and/or cold, so a wide operating temperature functionality is recommended, from –20 up to +55 celcius degrees.

- Does the telephone incorporate VSQ – Voice Sound Quality? This is a standard feature in all Norphonic telephone systems, ensuring loud and clear sound, even in noisy ambiance areas.

- Does the VoIP telephone incorporate a QoS – Quality of Service functionality? This feature, found in all Norphonic telephones, guarantees a certain level of performance in a data flow, ensuring impeccable delivery of voice communications in an IP Network.

- Is the telephone body, keypad, cord and handset able to withstand corrosion from the geothermal gases? Norphonic has a coated Aluminium body designed for underground mining and can withstand geothermal gases up to 20% sulphur and 3% hydroperoxid. The corrosion-resistant Norphonic telephone can therefore be installed in all mineral mine-sites, including copper, gold, platinum, iron ore, nickel, diamond or zinc mines.

- Is the telephone colored in such a way that it is easily identified by users? The Norphonic Heavy Duty VoIP comes in a bright yellow color as standard. Colors can also be customised depending on the user needs and order volumes.

- Is the system easy to install and to maintain? Norphonic Heavy Duty VoIP telephones are easy to install and have in-built status monitoring and fault check functions. This means that the status of the telephones can be monitored from a remote location, saving you considerable maintenance costs.

- Is the telephone CE approved? CE marking means that the product is certified to meet EU consumer safety, health or environmental requirements. End users should be aware that some telephones use the intentionally confusing term ”CE” for ”China Export”, and the only way consumers can check this is to closely examine the CE mark/ logo as the two logos are very similar.

- Can you obtain local service in case you need replacement parts or installation support? Norphonic VoIP telephones are often used in mineral mines, including copper, gold, platinum, iron ore, nickel, diamond or zinc mines and can be supplied by local vendors in South Africa, Australia, United States, Canada, Mexico, Chile, Indonesia and Russia. Contact Norphonic today to find out more, or obtain a quote for your mine.

Important Copyright Notice

All content on this page is created by Norphonic. This content is owned by Norphonic and you agree not to copy, communicate to the public, adapt, distribute, transfer, sell, modify or publish any contents of this web page without express pror written consent from the owner. Norphonic and all other trademarks used in this web-page are trademarks of their respective owners.